Thanks Boris!

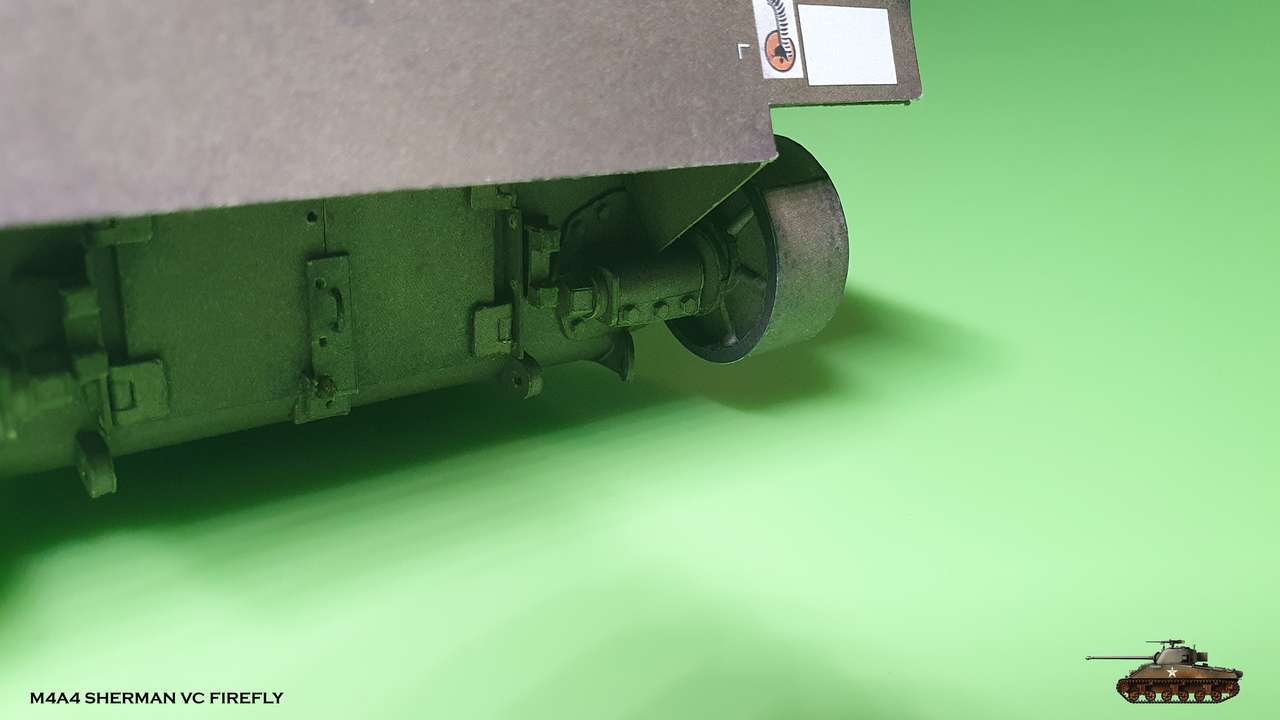

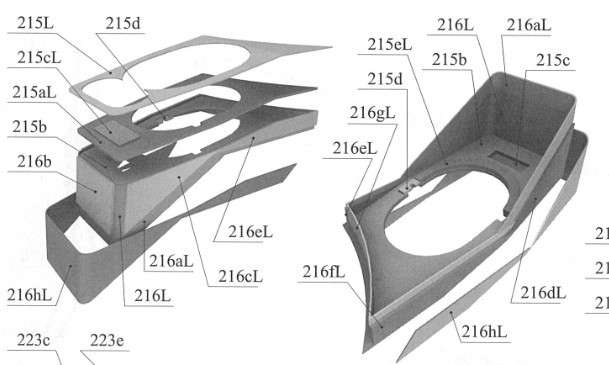

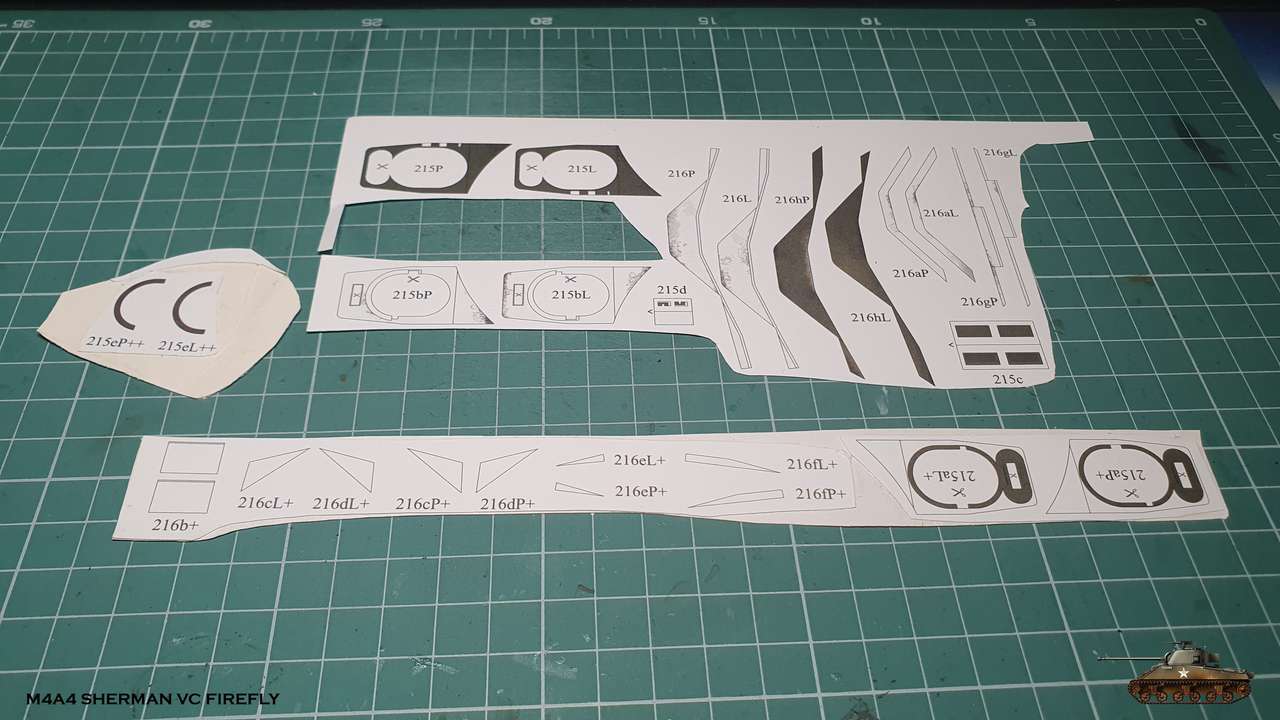

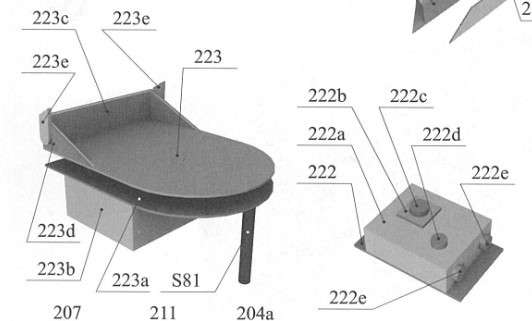

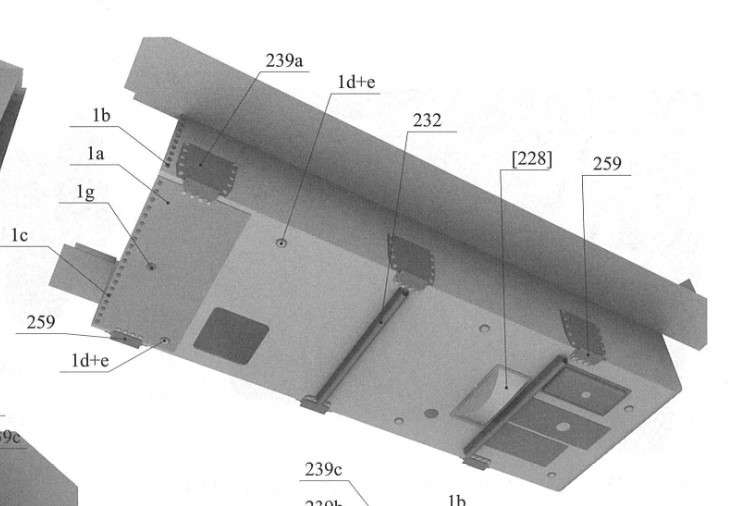

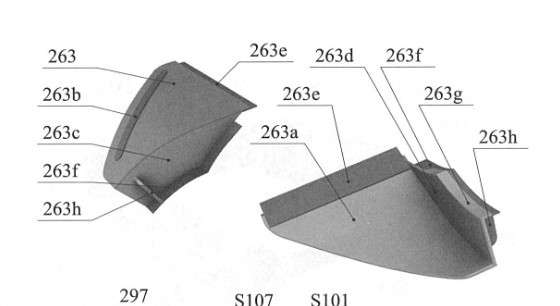

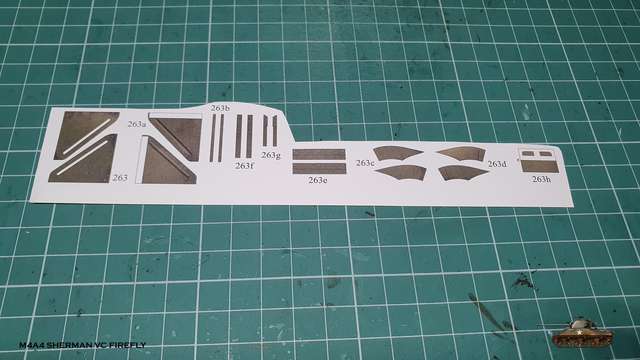

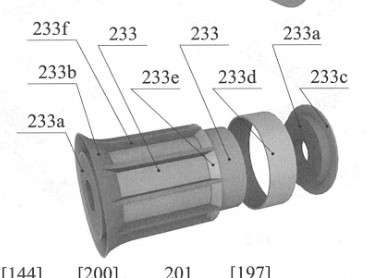

Front hatch towers assemble. Another thing that i met for first time - fragmented power frame.

I glued it first to inner skin, then skin to top and then outer skin.

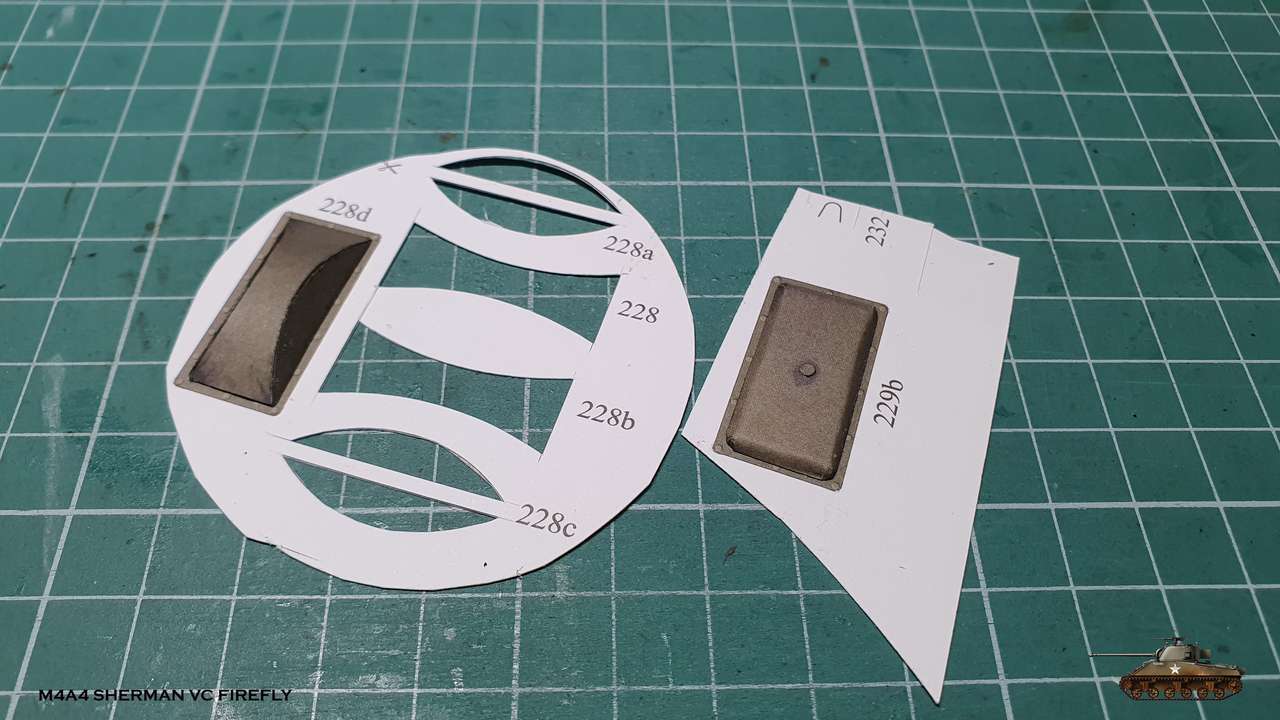

Also there is another cushion inside + locking mechanism.

Couple of strips frame edges of hatch

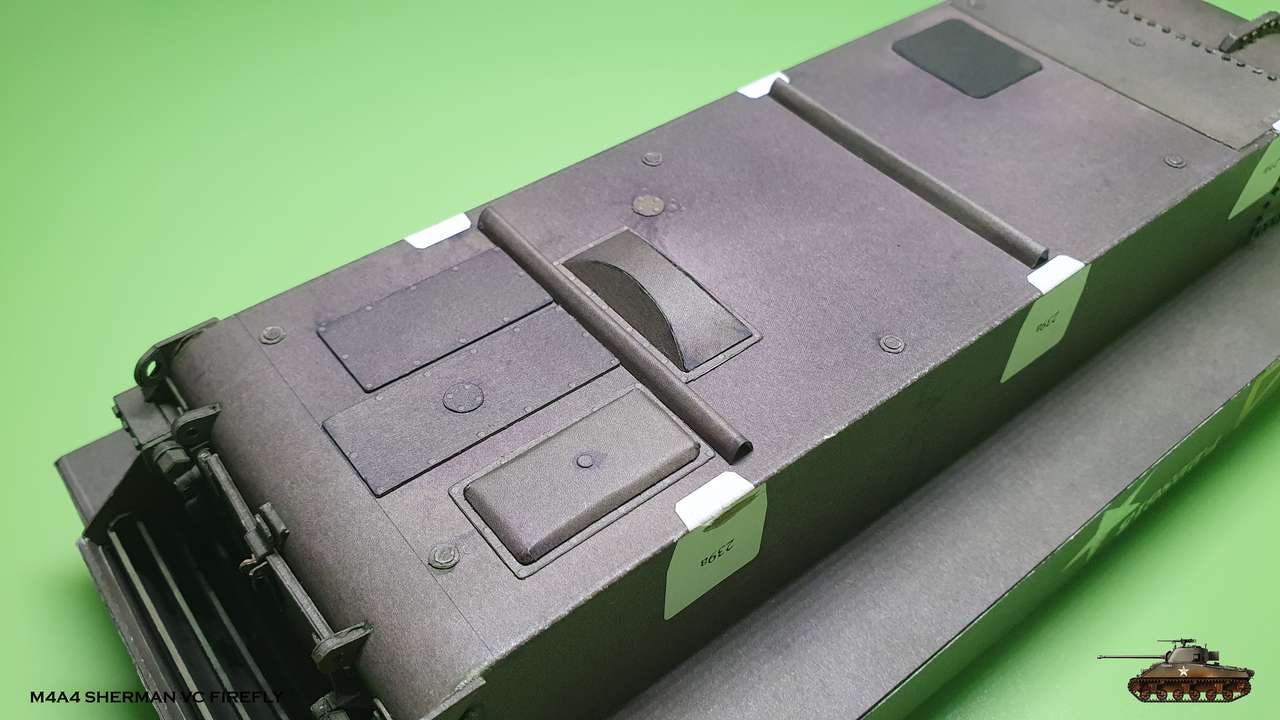

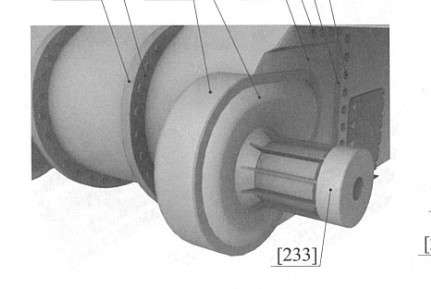

Towers connected well to the body, no adjustments needed.

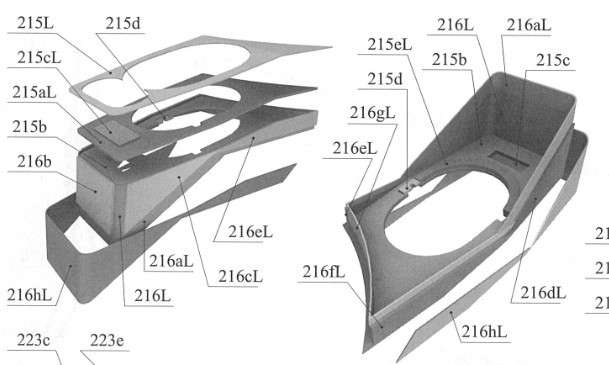

Front hatch towers assemble. Another thing that i met for first time - fragmented power frame.

I glued it first to inner skin, then skin to top and then outer skin.

Also there is another cushion inside + locking mechanism.

Couple of strips frame edges of hatch

Towers connected well to the body, no adjustments needed.

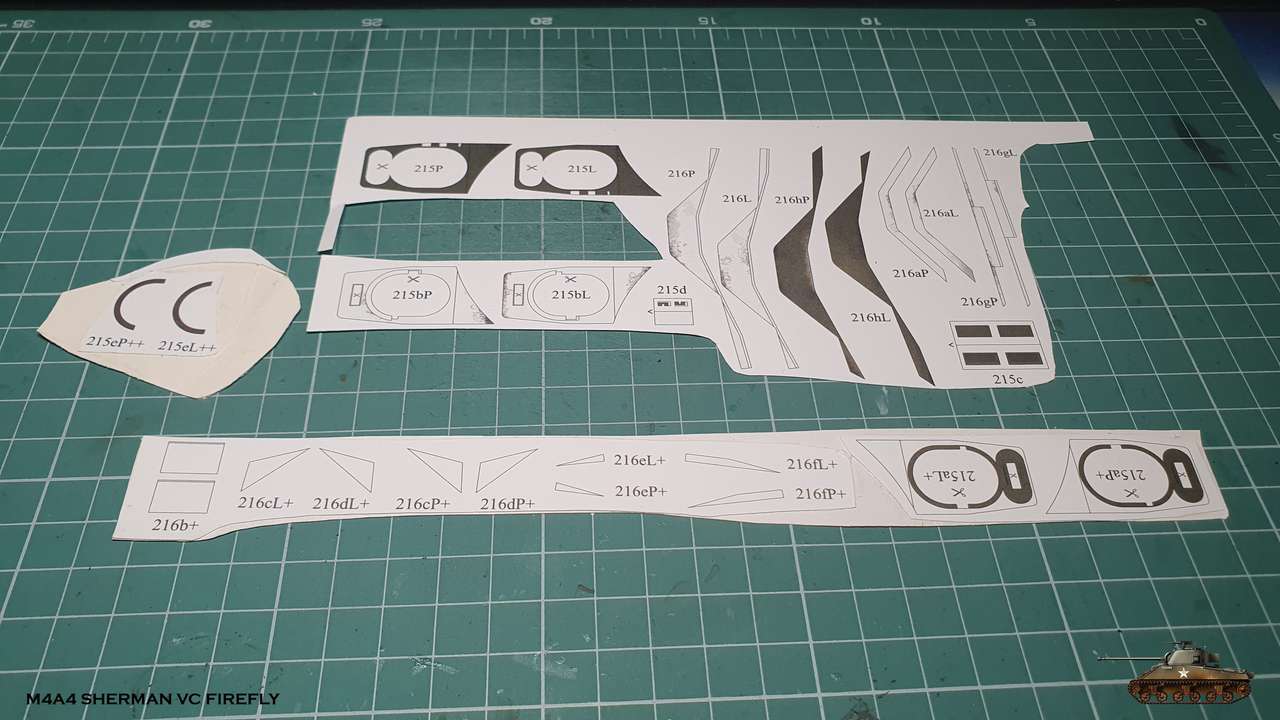

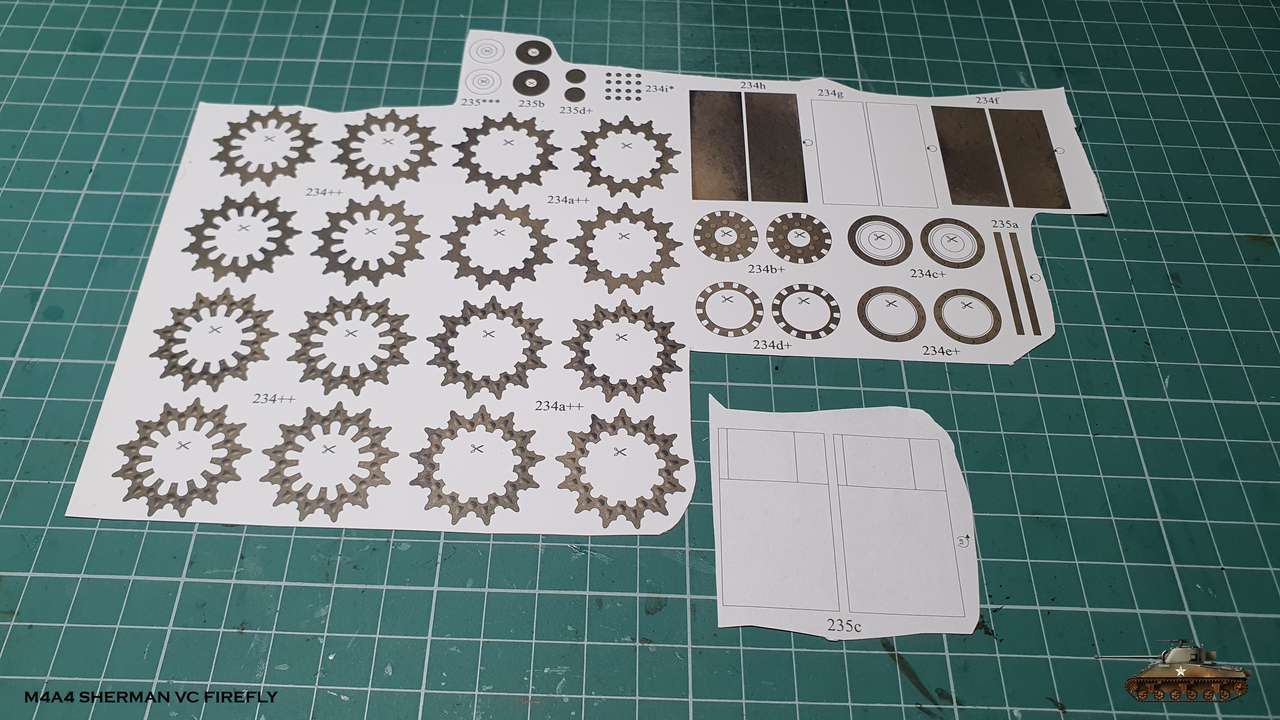

This is realy next level building. How is it possible to get those pretty cut lines. Everything is crisp and clear.

This is realy next level building. How is it possible to get those pretty cut lines. Everything is crisp and clear.