Dr Theopolis 1:1 scale from Buck Rogers

- Thread starter Revell-Fan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Indeed there are!

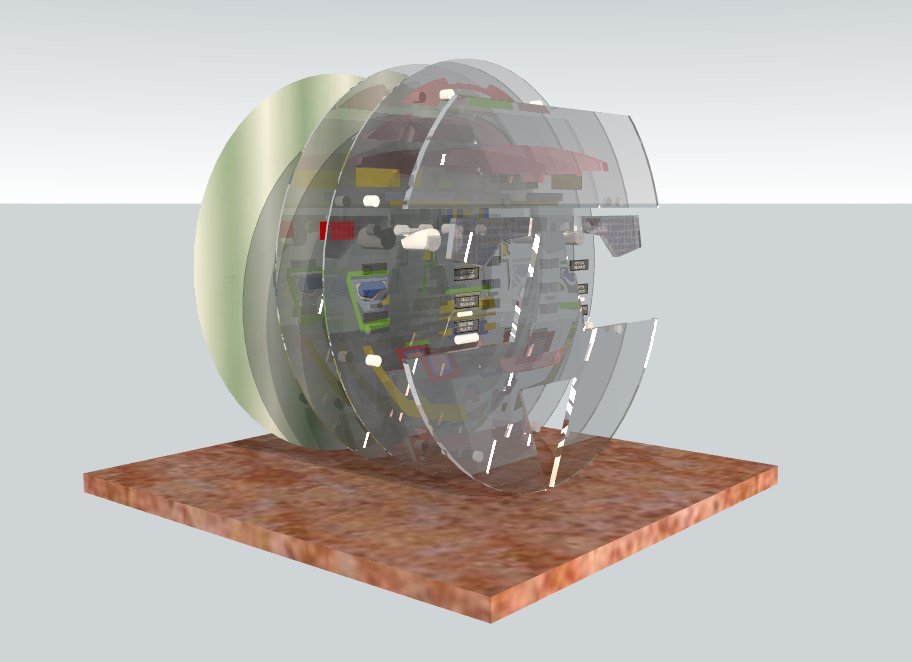

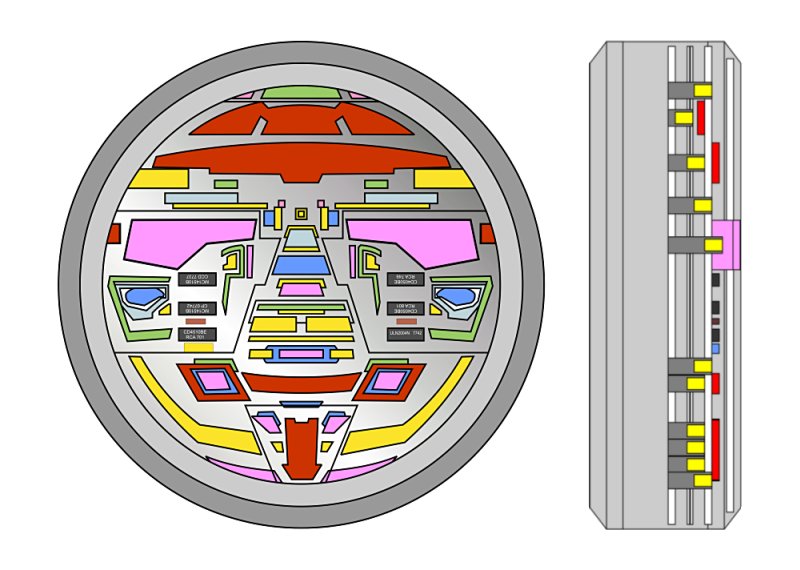

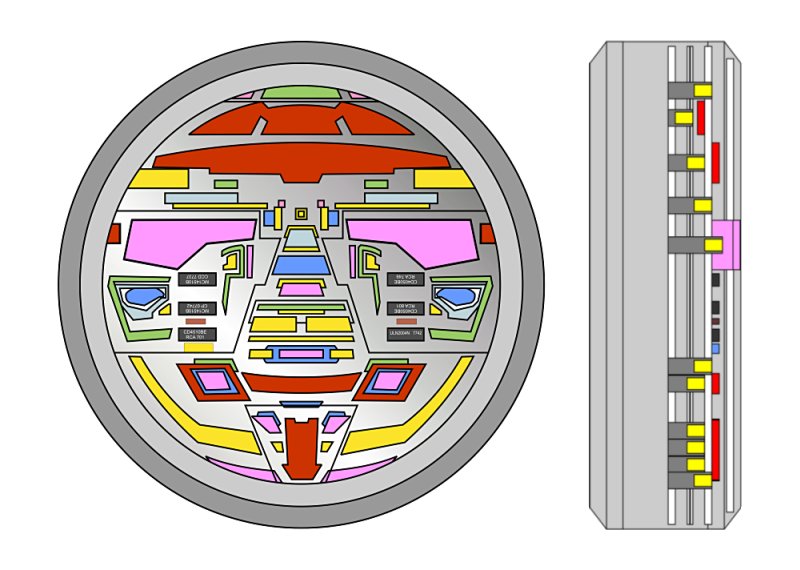

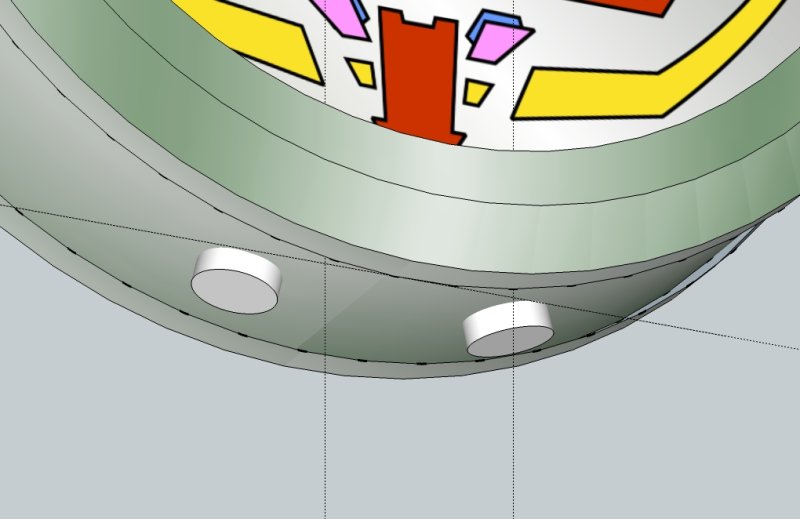

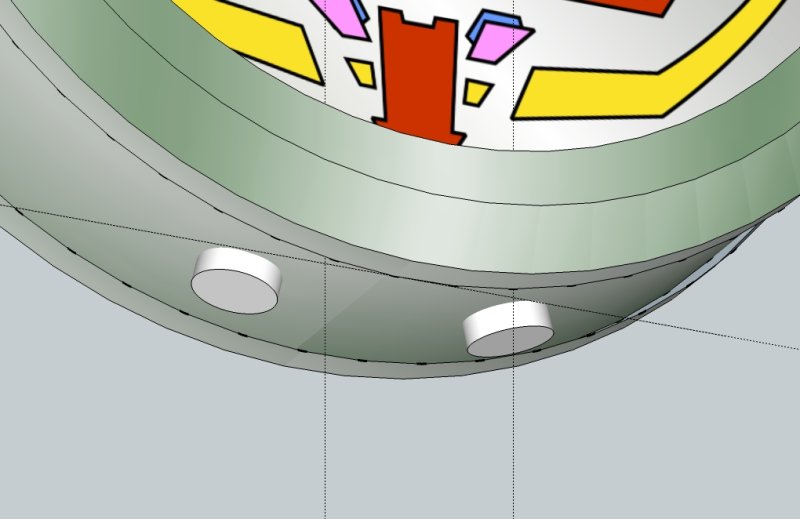

This image shows the layer structure better:

Yellow are the LED positions, the white parts are layers mainly of acrylics save for the layer in the middle of the cake tin which will be silver mirrored card. I'm looking forward to printing because it will be the first time for me to print on tranparent sheet!

This image shows the layer structure better:

Yellow are the LED positions, the white parts are layers mainly of acrylics save for the layer in the middle of the cake tin which will be silver mirrored card. I'm looking forward to printing because it will be the first time for me to print on tranparent sheet!

Last edited:

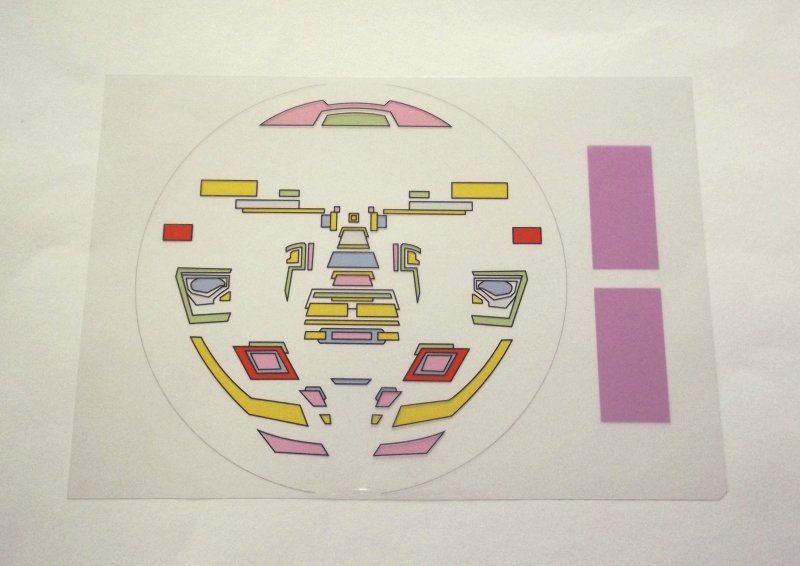

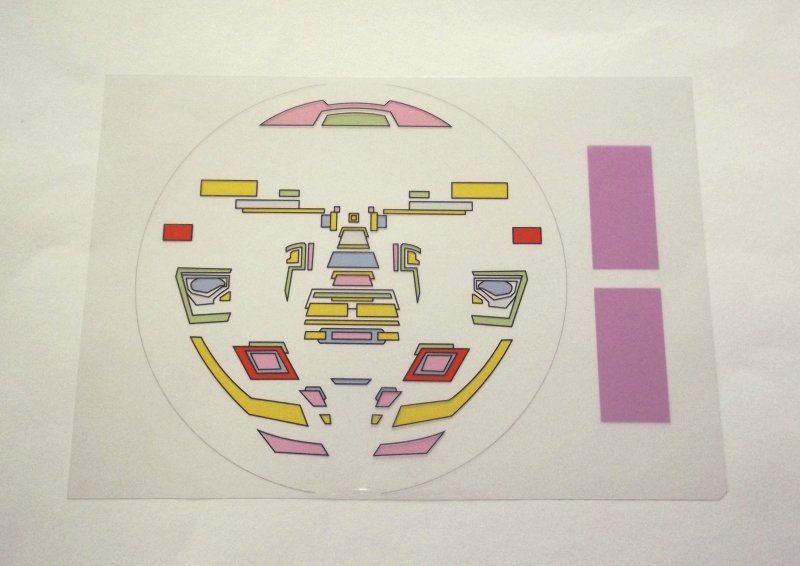

Some progress. I have managed to print Theo's face on transparent sheet. It was easier than I first thought. Just follow the instructions that come with the sheets and use the correct setting of your printer (I use an HP inkjet).

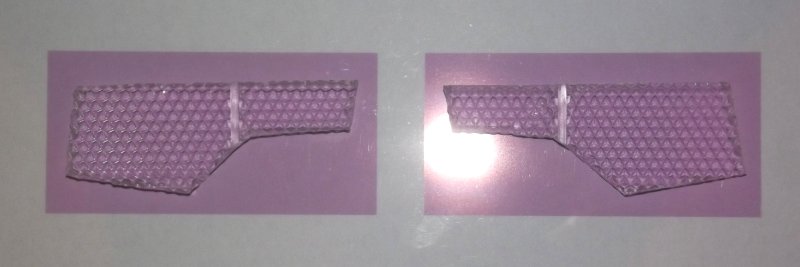

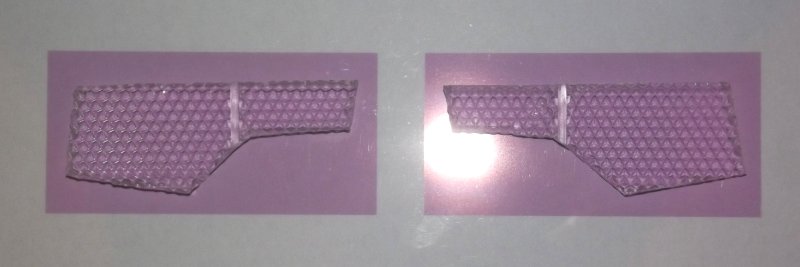

As you can see I also printed two purple rectangles along with the face. These will become the colour sheets for the transparent eyes.

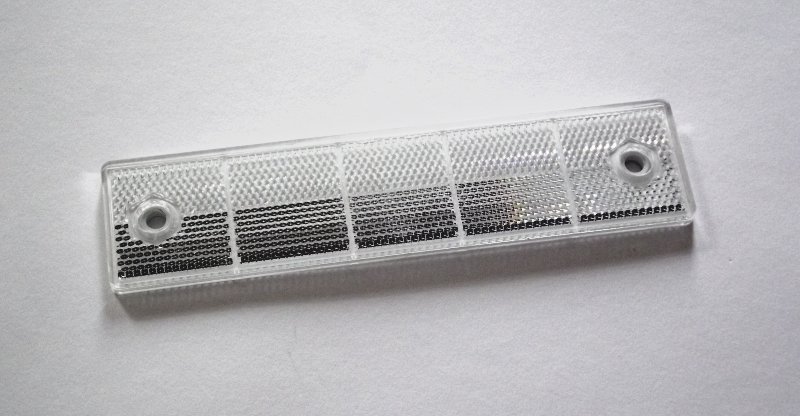

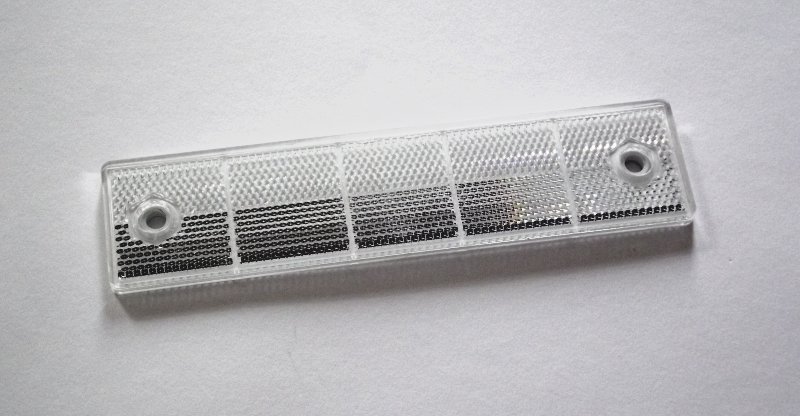

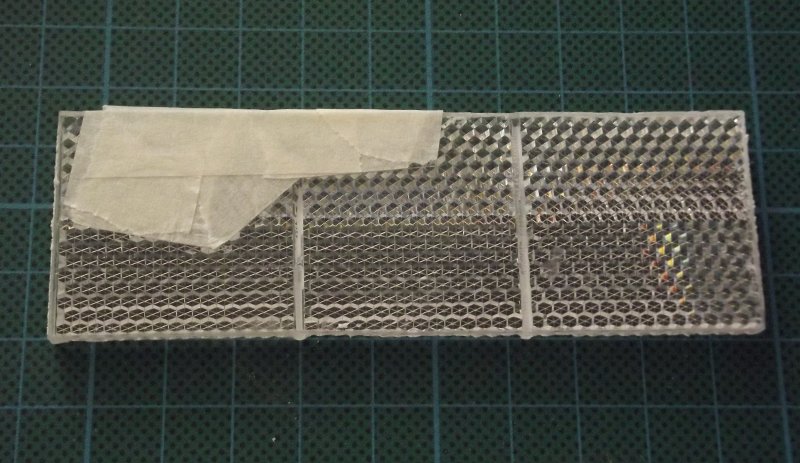

The "eyes" will be made of reflectors featuring a honeycomb structure or something like that. My uncle supplied me with some decomissioned reflector parts used in road constructions. They do not look exactly like Theo's eyes but they will do their job (I hope ;-) ).

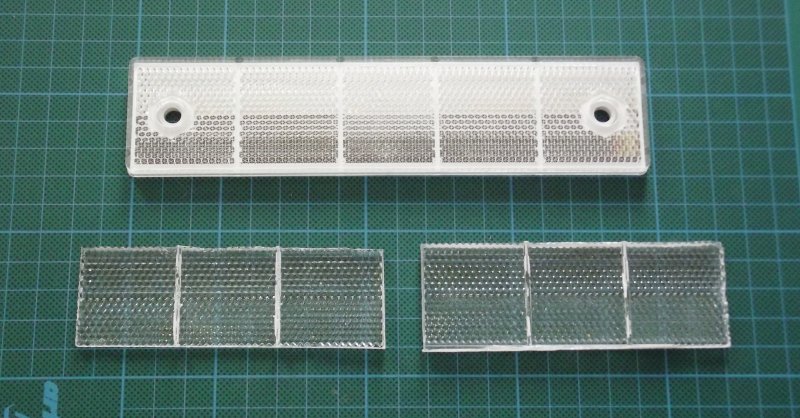

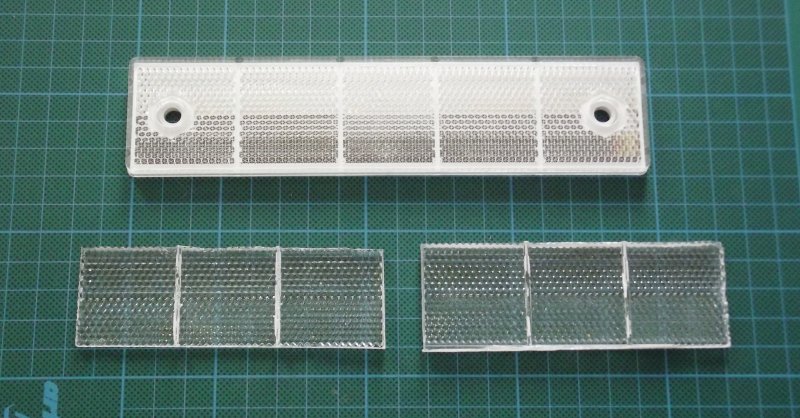

They are taken apart with a saw. The reflector part is turned around so that its structure is facing up.

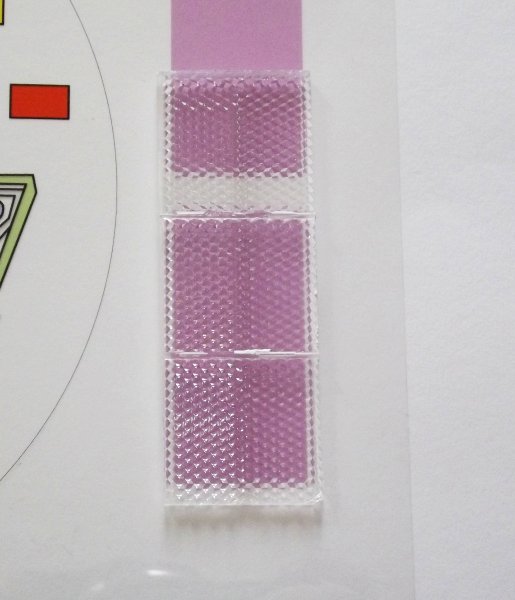

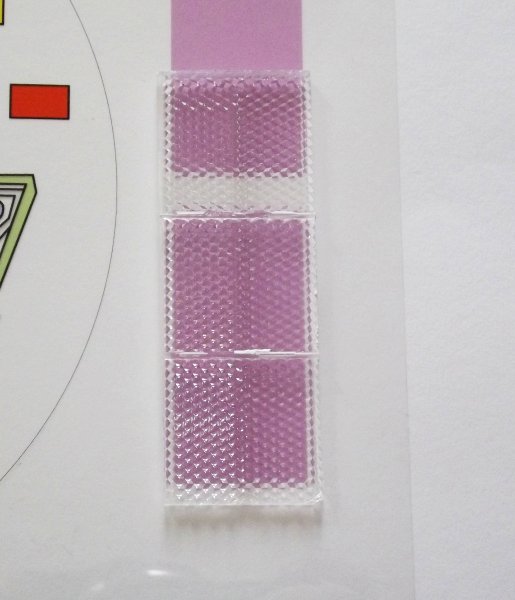

A small test shows how the colour piece will look on the reflectors.

Now I'll have to cut the pieces to shape. I have never done anything like that so I am really looking forward to the results. If everything proceeds as planned the final reflector pieces will be turned into a pattern to texture the eye parts of the paper version.

Stay tuned!

As you can see I also printed two purple rectangles along with the face. These will become the colour sheets for the transparent eyes.

The "eyes" will be made of reflectors featuring a honeycomb structure or something like that. My uncle supplied me with some decomissioned reflector parts used in road constructions. They do not look exactly like Theo's eyes but they will do their job (I hope ;-) ).

They are taken apart with a saw. The reflector part is turned around so that its structure is facing up.

A small test shows how the colour piece will look on the reflectors.

Now I'll have to cut the pieces to shape. I have never done anything like that so I am really looking forward to the results. If everything proceeds as planned the final reflector pieces will be turned into a pattern to texture the eye parts of the paper version.

Stay tuned!

Last edited:

Cforrest900

Well-Known Member

Doctor Who?This is the kind of stuff I live for in this hobby! Somebody get me a Doctor!

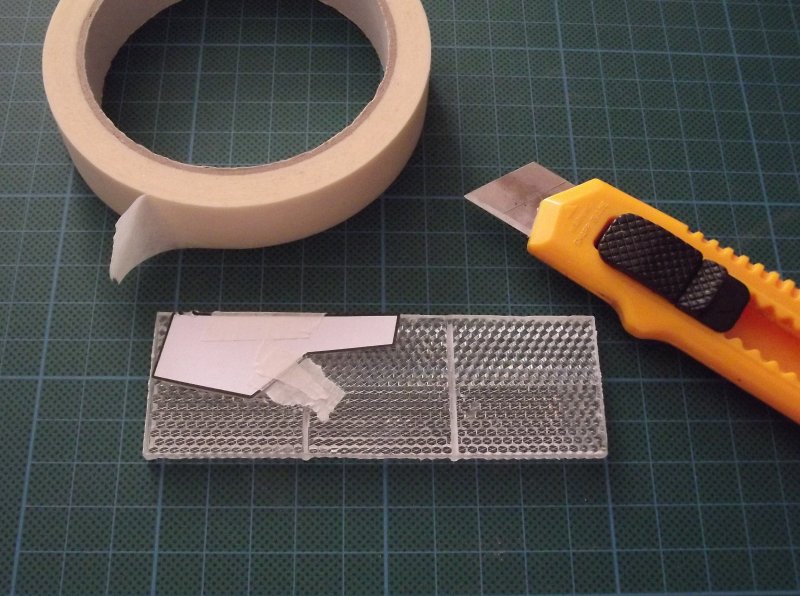

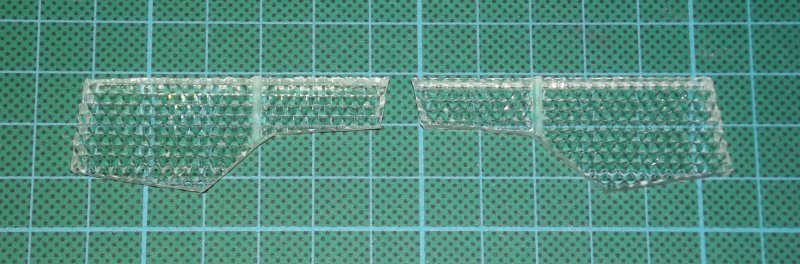

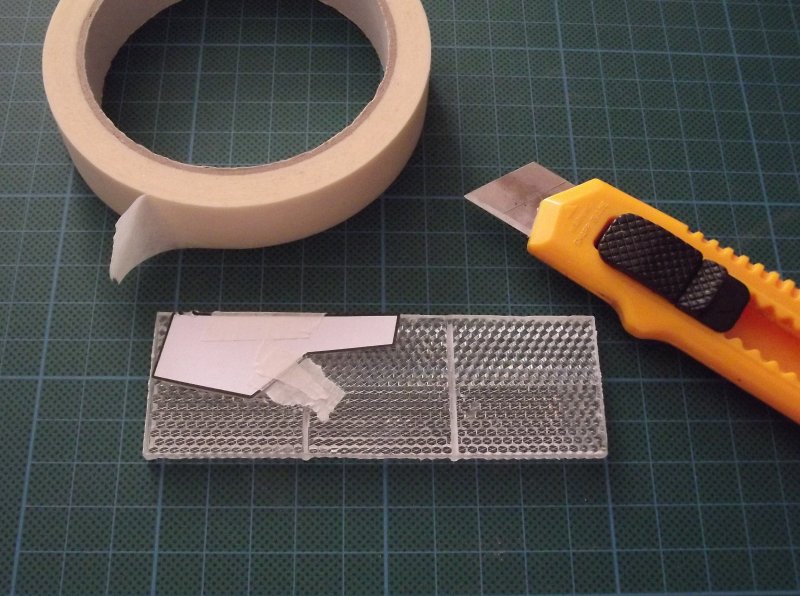

Today I have cut out the eyes. First I taped a template to the smooth (back) side of the reflector and traced the outline with my cutter and a metal ruler.

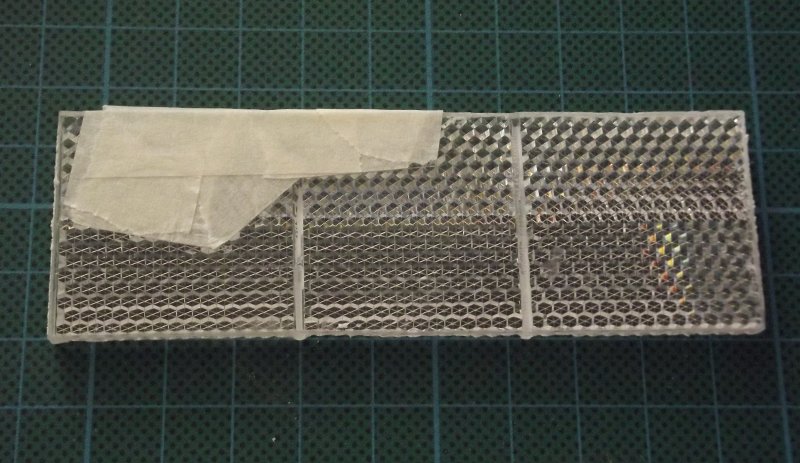

I removed the mask and protected the inside with removable tape to protect it from being damaged by accident.

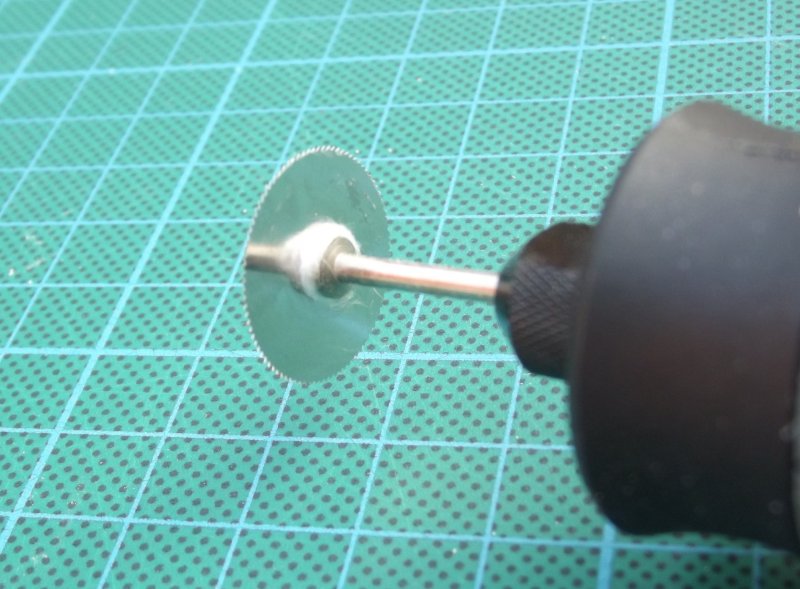

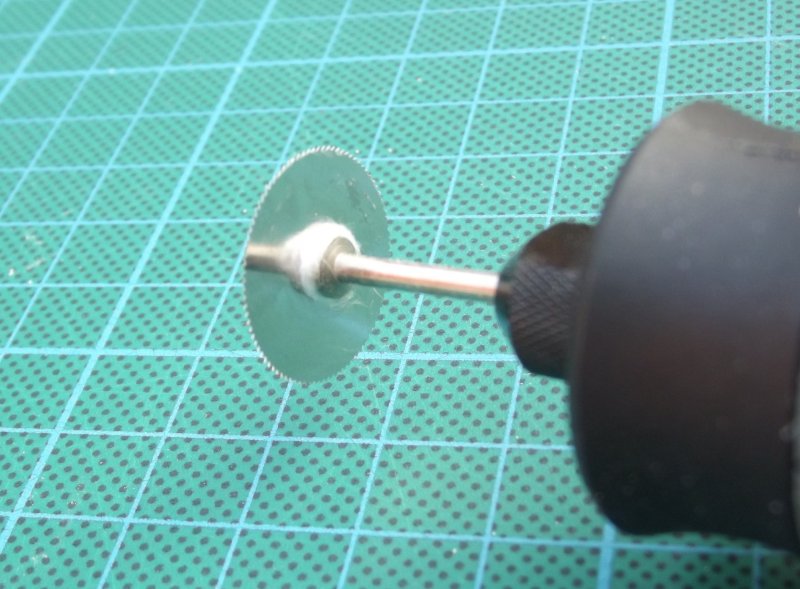

Then the cutting began. It is said that cutting at high speed would be dangerous because the material would melt and damage the part and the machine. So I started at minimum speed and took a short break every minute to allow the part to cool off. This procedure was a bit too slow for my taste and I increased the speed of the machine to medium.

Everything worked as planned. Nothing melted. When I was cutting out the second eye I became tougher and switched to high speed! It worked but I was attacked by flying bits and pieces of hot reflector material. The parts got really HOT and felt like needle stitches where they hit my skin. However, that way I was able to cut out the part much faster. Man and machine remained unharmed during the process (I was wearing my goggles

However, that way I was able to cut out the part much faster. Man and machine remained unharmed during the process (I was wearing my goggles  ).

).

When I separated the rotating blade from the machine I noticed something weird: Some of the reflector material had turned into some sort of "candy floss"!

However, disassembly and cleaning was very easy.

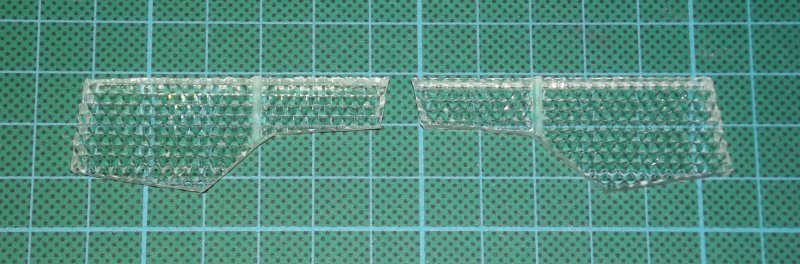

The rim was sanded smooth and the eye parts were ready for further assembly.

A quick foil test to check the colour:

Yummy!

I removed the mask and protected the inside with removable tape to protect it from being damaged by accident.

Then the cutting began. It is said that cutting at high speed would be dangerous because the material would melt and damage the part and the machine. So I started at minimum speed and took a short break every minute to allow the part to cool off. This procedure was a bit too slow for my taste and I increased the speed of the machine to medium.

Everything worked as planned. Nothing melted. When I was cutting out the second eye I became tougher and switched to high speed! It worked but I was attacked by flying bits and pieces of hot reflector material. The parts got really HOT and felt like needle stitches where they hit my skin.

When I separated the rotating blade from the machine I noticed something weird: Some of the reflector material had turned into some sort of "candy floss"!

However, disassembly and cleaning was very easy.

The rim was sanded smooth and the eye parts were ready for further assembly.

A quick foil test to check the colour:

Yummy!

Last edited:

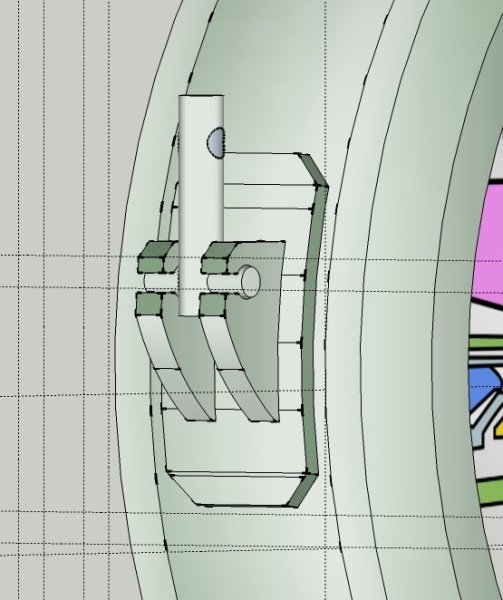

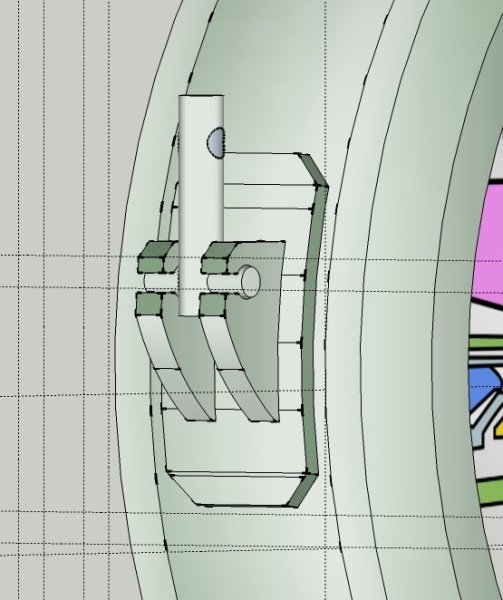

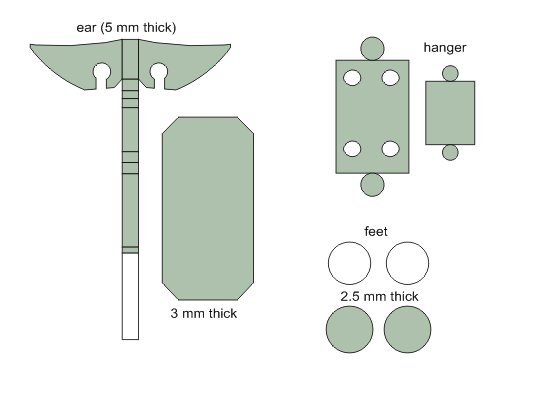

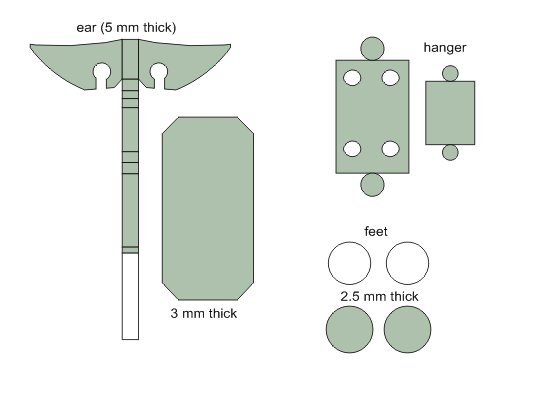

I continued working on Theo's SketchUp model. Now he has some "ears" and "feet":

The first pieces of the "cake tin" have been unfolded. Here is a sample of the "ears" and the "feet":

It would really be cool if the team behind the Battlestar Galactica redux would tackle Buck Rogers.

I would have to agree with you. I too think that it would be cool to have BRTC25 remade like BSG. So long as who ever did such was able to keep the general design and iconic look of the Thunder Fighter (and not make TOO MANY drastic changes).

Hello, fans!

Not really an update but a small info:

Today the forum has been enriched by a few more sections, including a section for "Mixed Media". Since I'm using quite a bit of acrylics on this project I have asked RB to move this thread from the Sci-Fi section to the Mixed Media section. It is the VERY first thread here and in a way a "(formal) opening" .

.

The new look, a Facebook page, new sections, new members and creativity everywhere - Zealot is truly growing and evolving!

Have fun and enjoy!

RF

Not really an update but a small info:

Today the forum has been enriched by a few more sections, including a section for "Mixed Media". Since I'm using quite a bit of acrylics on this project I have asked RB to move this thread from the Sci-Fi section to the Mixed Media section. It is the VERY first thread here and in a way a "(formal) opening"

The new look, a Facebook page, new sections, new members and creativity everywhere - Zealot is truly growing and evolving!

Have fun and enjoy!

RF

I know, me too!  Please be patient, the project is continued soon. I still have to figure out the blinking scheme of Theo's lights (not the ones behind his eyes but the ones behind his face plate).

Please be patient, the project is continued soon. I still have to figure out the blinking scheme of Theo's lights (not the ones behind his eyes but the ones behind his face plate).