Now THAT's prototype modeling! It's work beyond even the greatest of superlatives!! Truly breathtaking. I doubt anyone else here on this forum, (maybe NKP175) has the paitence to do this. It's just...WOW!

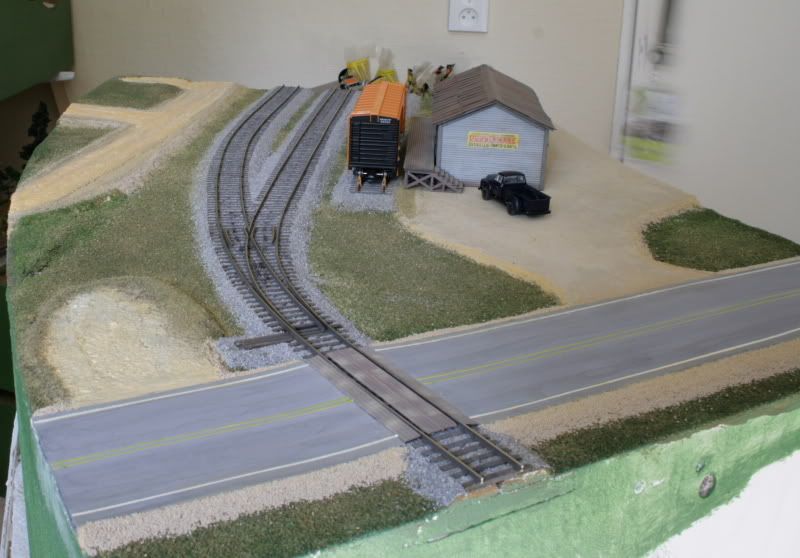

Golden Valley module

- Thread starter ulf999

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Thanks [ ]

]

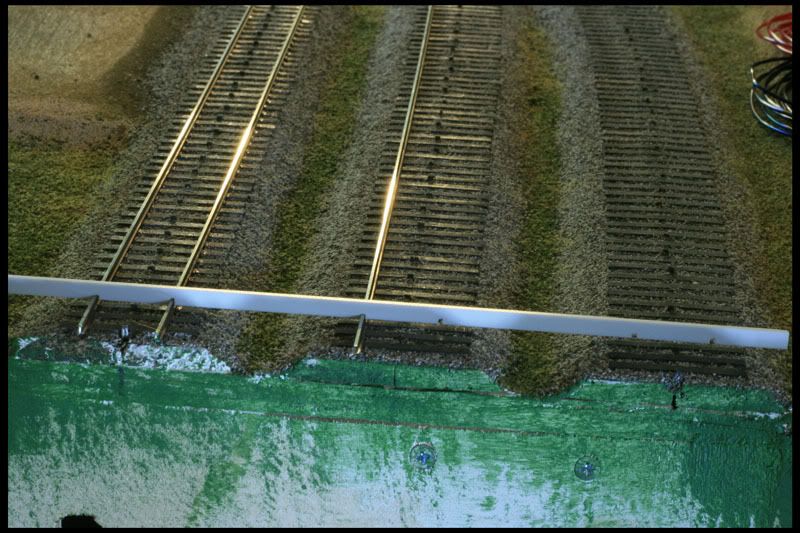

A few more pics. I have now glued the other rail and ran some tests. It works!!!

I have used PS D&RGW building brown to simulate rust (this is a spur, the mainline will be painted roof brown...)

When more thing are in place (a few years from now... ) I will further weather the track with washes and powder)

A few more pics. I have now glued the other rail and ran some tests. It works!!!

I have used PS D&RGW building brown to simulate rust (this is a spur, the mainline will be painted roof brown...)

When more thing are in place (a few years from now... ) I will further weather the track with washes and powder)

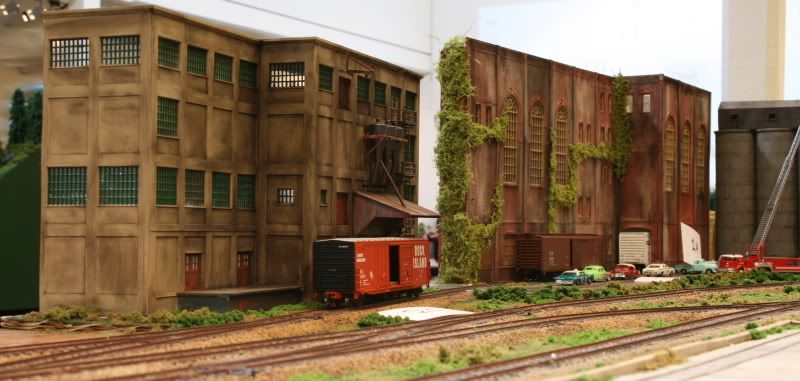

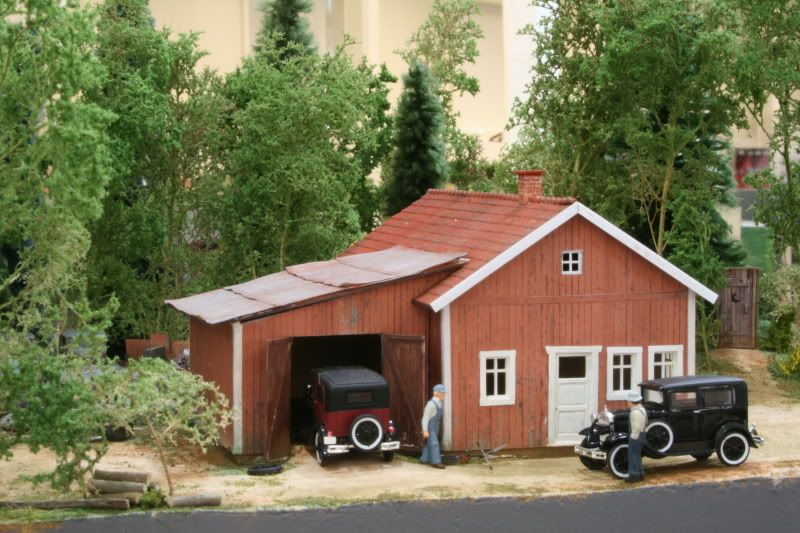

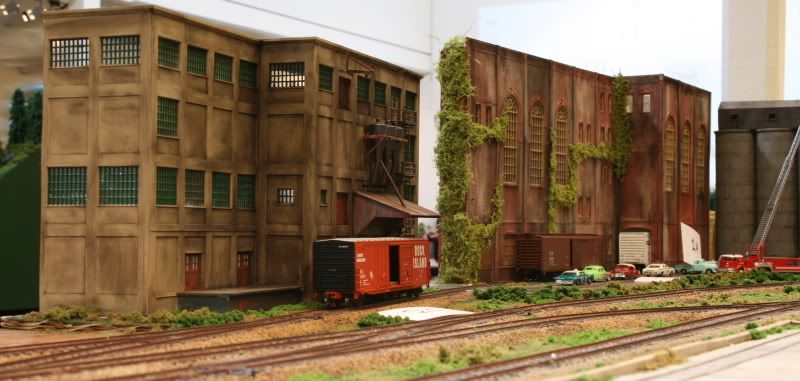

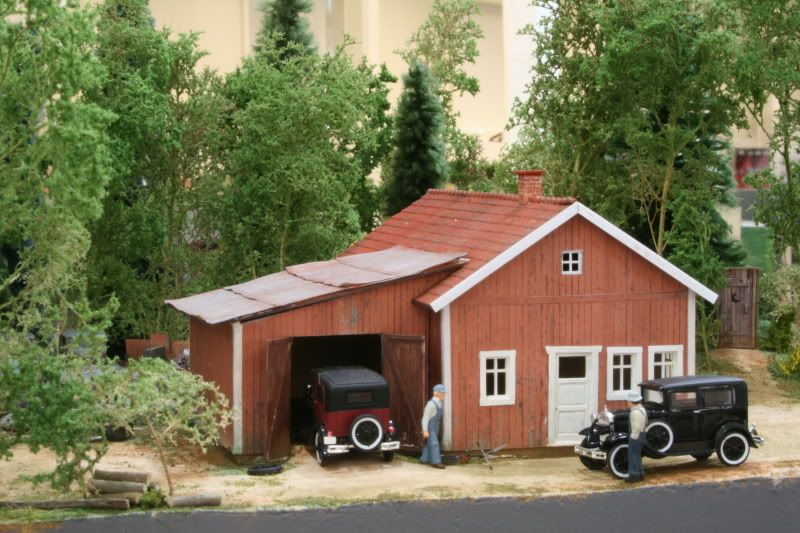

Here are a few pics from a modular meeting at a museum last weekend

ulf999/MMM/Meetings/TM_20080329 - Photobucket - Video and Image Hosting

ulf999/MMM/Meetings/TM_20080329 - Photobucket - Video and Image Hosting

At last, I got some (hobby) time. I've given the turnout a whack.

I gave up using tieplates on this one. The reason is that I'm using the tongues as studs for the pickup shoe (when running in 3R mode). The tieplates (metal) would short circuit the whole thing since they connect between the stockrails and the tongues

So I just keep-it-simple (well... ))

))

The throwbar is soldered and all but the (outer) railguards are in place. DC and AC cars seem to like the frog

If you zoom the centre of this pics, you'll notice that there is a cut in the tongues to isolate them. They will individually be powered using a relay (driven by one of the tortoise's relayes) More on this later on...

The throwbar is a copperclad PC-tie from fasttrack. It has been isolated to avoid shortcircuits when running in 2R-mode.

Work will soon continue with the remaining rail (seen loose in some of the pics...)

I gave up using tieplates on this one. The reason is that I'm using the tongues as studs for the pickup shoe (when running in 3R mode). The tieplates (metal) would short circuit the whole thing since they connect between the stockrails and the tongues

So I just keep-it-simple (well...

The throwbar is soldered and all but the (outer) railguards are in place. DC and AC cars seem to like the frog

If you zoom the centre of this pics, you'll notice that there is a cut in the tongues to isolate them. They will individually be powered using a relay (driven by one of the tortoise's relayes) More on this later on...

The throwbar is a copperclad PC-tie from fasttrack. It has been isolated to avoid shortcircuits when running in 2R-mode.

Work will soon continue with the remaining rail (seen loose in some of the pics...)

Even without the tie plates, still in the 99th percentile for beauty!

I believe you were looking for the english term "frog" for the heart shaped part.

I believe you were looking for the english term "frog" for the heart shaped part.

More progress.

I've been pre-drilling the spikeholes in the ties and aligning some rail . As you can see, I'm dropping a wire for each rail...

since I will have 3 tracks that have to match when I connect the segments, I opted for a simple jig (styrene...). The track spacing is 6cm

The spikes are driven down at an angle (easier to 'post adjust' things this way...). Also make sure the spikes don't 'line up'. They'll split the tie...

When the inner track was done, I had to wire things up and let my good ol' UP Alco PA do a test run

One of the tongues is wired (and locked in position...) to act as a 'big stud' (later it will be polarized using the Tortoise...)

I had to resolder the throwbar and 'inner tongue', widening the gap so that the wheels wouldn't short circuit the whole thing. And I'll be darned! It works!!!

Here one can spot the slider and the wheels. The (Herbert-Herei) studs only reach the top of the rails, so I figure that 2R (DC...) engines/cars will have no problems [ ]

]

I've been pre-drilling the spikeholes in the ties and aligning some rail . As you can see, I'm dropping a wire for each rail...

since I will have 3 tracks that have to match when I connect the segments, I opted for a simple jig (styrene...). The track spacing is 6cm

The spikes are driven down at an angle (easier to 'post adjust' things this way...). Also make sure the spikes don't 'line up'. They'll split the tie...

When the inner track was done, I had to wire things up and let my good ol' UP Alco PA do a test run

One of the tongues is wired (and locked in position...) to act as a 'big stud' (later it will be polarized using the Tortoise...)

I had to resolder the throwbar and 'inner tongue', widening the gap so that the wheels wouldn't short circuit the whole thing. And I'll be darned! It works!!!

Here one can spot the slider and the wheels. The (Herbert-Herei) studs only reach the top of the rails, so I figure that 2R (DC...) engines/cars will have no problems [

Drilling the ties as in pre-drilling the spike holes? I had to do that for my yard of HOn3 track.

Drilling the ties as in pre-drilling the spike holes? I had to do that for my yard of HOn3 track.

yes, I've corrected the text

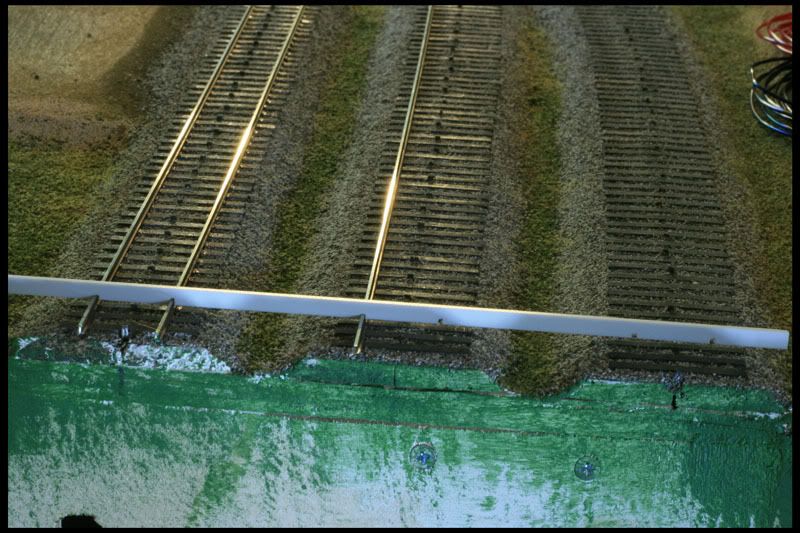

All the track in place, alas the inner radius is a mere 40cm. I'll have to do better calculations on the following sections.

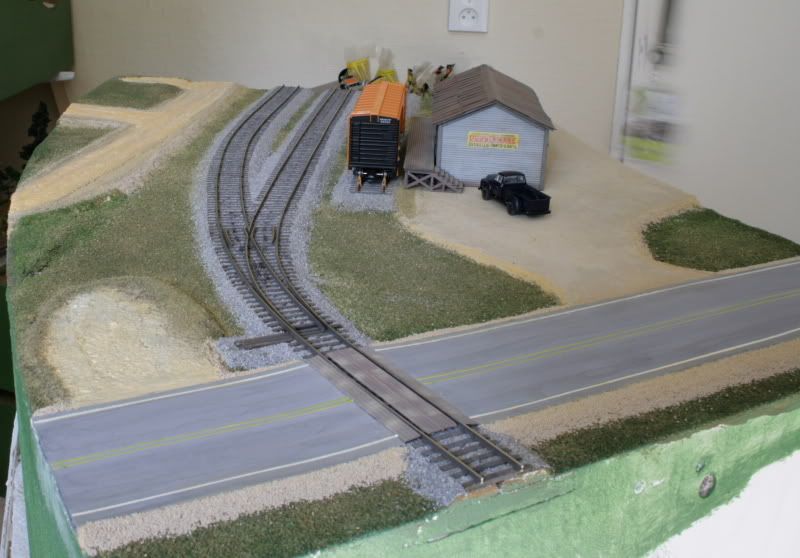

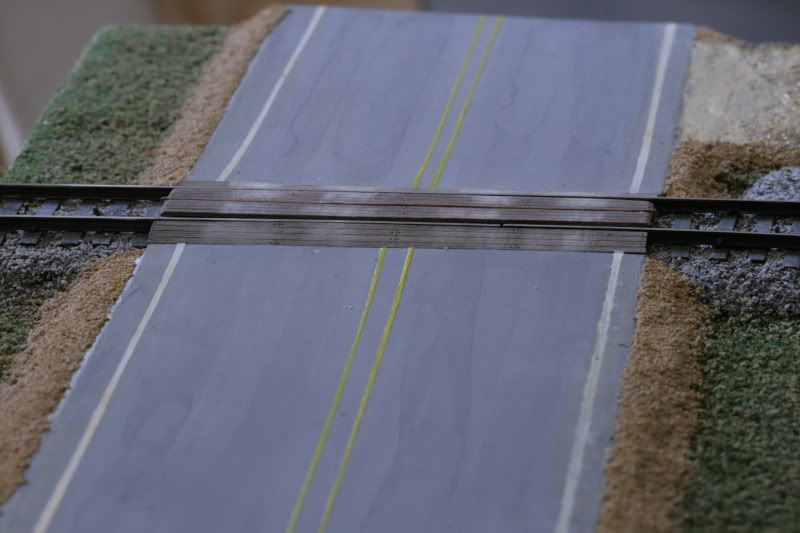

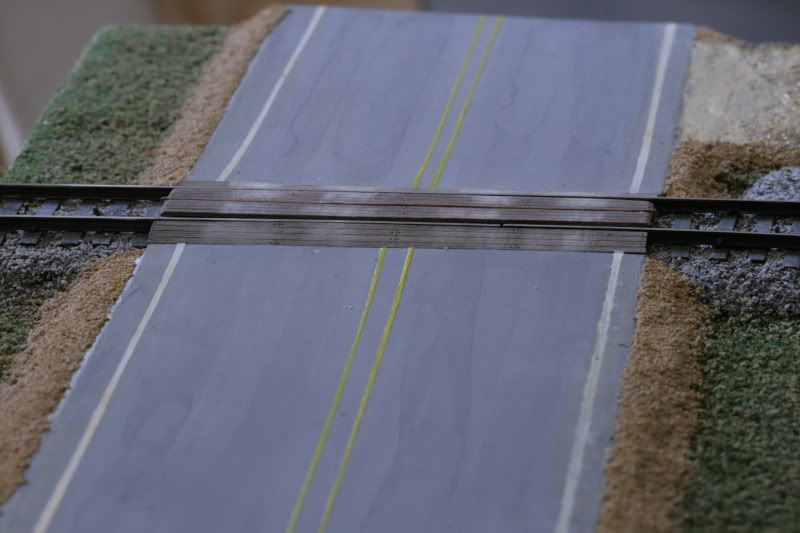

Work has now continued with the road and the Bar mills crossing:

I had to improvise so that the crossing is level with the track

The road is a sheet of Evergreen styrene (0.020) that I applied with latex caulk.

Tomorrow (?) I'll add the 'center piece'. It has a thin copper wire providing the slider with something to pick up ...

...

Work has now continued with the road and the Bar mills crossing:

I had to improvise so that the crossing is level with the track

The road is a sheet of Evergreen styrene (0.020) that I applied with latex caulk.

Tomorrow (?) I'll add the 'center piece'. It has a thin copper wire providing the slider with something to pick up

Good looking trackwork & modules, Ulf. I'm glad to read of your experience with handlaying the track with the tieplates and deciding to switch to the MicroEngineering track - I've looked into the P:87 Stores products as I think tie plates (and retaining clips) are an important detail that is usually missing from handlaid track; the thing that bothers me about the etched plates is the lack of spike detail anchoring the rail to the plates. I'm planning on using a combination of MicroEngineering track and Central Valley tie strips, with molded spike detail that gets 'folded' over the rail 2000 index htm And I'll be ordering the etched tie plates as a detail item - they are very nice.

Some more work put into the project (with its ups and downs)...

From a distance the road looks quite ok...

...but as one can see, I did a 'selective de-compression' of the distance between the yellow road markings.:curse:.That's what might happen when the enthusiasm takes precedence over 'Think!'. I guess I'll have to re-paint :cry:wall1

For the spur, I've added some 'Hayes wheelstops' (Tomar Industries). I'm quite happy with the looks of them

What I'm struggling with now is the transition from my gravel area (painted plaster) to the 'slope' where I've put some WS blended earth turf. Not quite happy with the result, so I'm thinking about what to do next here...

From a distance the road looks quite ok...

...but as one can see, I did a 'selective de-compression' of the distance between the yellow road markings.:curse:.That's what might happen when the enthusiasm takes precedence over 'Think!'. I guess I'll have to re-paint :cry:wall1

For the spur, I've added some 'Hayes wheelstops' (Tomar Industries). I'm quite happy with the looks of them

What I'm struggling with now is the transition from my gravel area (painted plaster) to the 'slope' where I've put some WS blended earth turf. Not quite happy with the result, so I'm thinking about what to do next here...