Possible Solution

Barry,

I've been thinking about ships rails for some time now and your dilemma brought the thought to the fore.

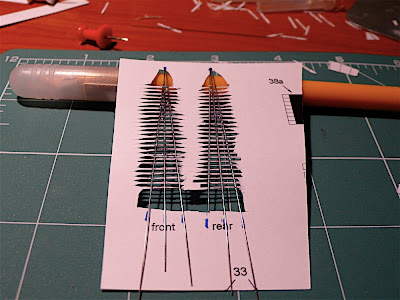

Basically, the thinking goes something like this; Use fixed basket weave style frame but instead let it be a parallelogram. If wire is placed between two opposing sides the strands will come ever closer as the structure is deformed into a diamond shape. The idea is to setup the wire on parallel sides which when positioned at say a 60 degree angle will be one half of what the distance was when the sides were perpendicular. So a one millimeter spacing would become 0.5 mm when angled at 60 degrees. The same can be done for the cross pieces. The whole idea is to gain miniature precision by a dividing technique and which will also hold the wire firmly in position while it's being soldered.

Also preparing the wire by pre-tinning it prior to rigging in the frames will simplify the soldering job. On second thought as long as the wire has a clean surface this could be performed with the wire already rigged in the frame. One las point is this method lends itself to making quite a few at one time.

-Gil