Some intriguing ideas.

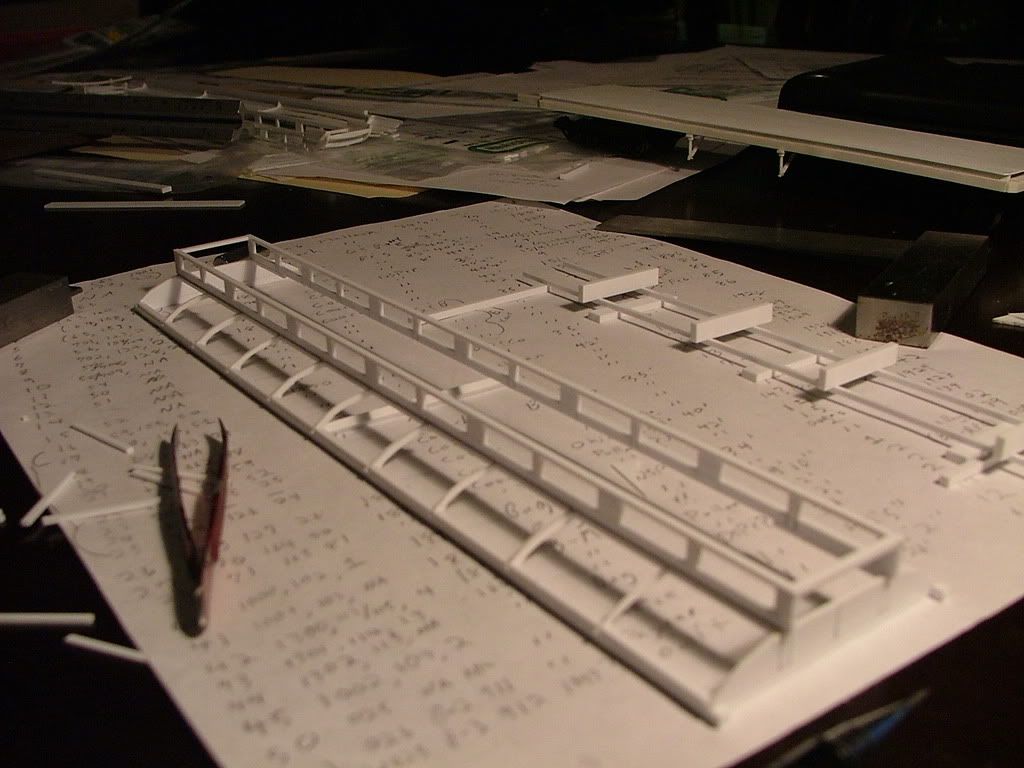

You can't see them, but there are supports running the length of the car...in between the arches. But, I am concerned with the middle sagging. I'm hoping that the clerestory will add some additional support...but it could still sag. I've got to do a good job of attaching the top for the clerestory so that it resists this bending.

Actually, come to think of it, the 0.010" thick styrene will have some spring to it which ought to pull the middle of the car up...as I'm not going to be heating & forming it.

Yes, the plan is for the roof to be removable. I won't be finishing the interior for a while (I can't find any sources for the interior of a pay car...aside from the basics: a safe, a pay master's desk, and a place to distribute the pay. When I do finish the interior, the roof will receive a layer of internal sheathing. Between now and then, I might add some additional supports...I stopped where I did because they were time consuming to make...and more importantly...my fingers started to cramp up while holding the tiny pieces to file them

.

Good ideas on the ends...I haven't given it too much throught yet...aside from that the fascia ought to be a single piece. Board by board definitely has much potential in applications like this. I've thought about it a few times...although not specifically for the end as you've described...where the 0.010" styrene would cause plenty of trouble.

I don't know if this car had a tin or canvas roof. I can recall around 5 years ago when I brought tissue from work to use for a canvas roof on a pair of MDC overton HOn3 kitbashed passenger cars...Which I never got around to completing. (although the combine is in service...just without couplers). It is good to know to be weary of using a solvent "glue" if I use the tissue paper method. I'm also considering the large scale masking tape method.

Btw, the roof is actually going to be 2 or 3 layers of 0.010" styrene...Which is the same approach I've used on my waycar.

Thank you for the tips!