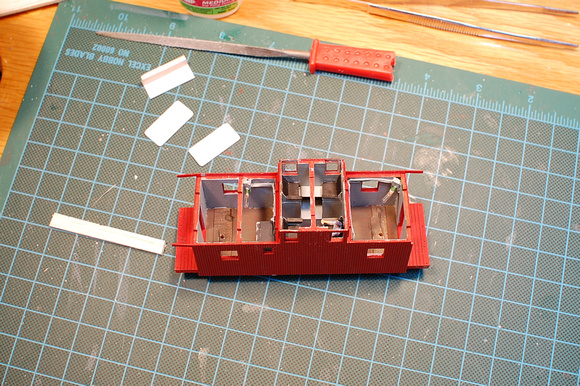

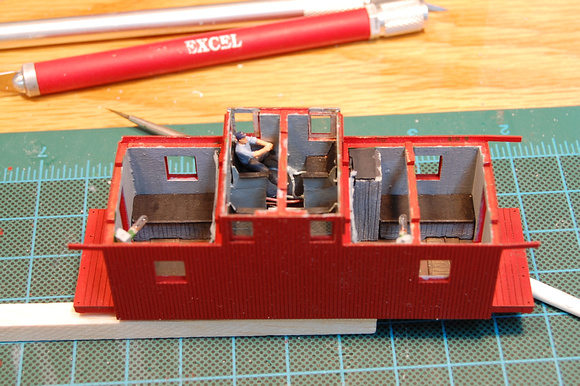

Those of you who have been around for more than a few months, were paying attention and have good memories may remember that I embarked on this caboose model awhile back. My last post about it was to ask questions about mixing the right red.

Since then I've worked on it off and on and decided it'd be worthwhile to post my progress (even if the updates are six months behind).

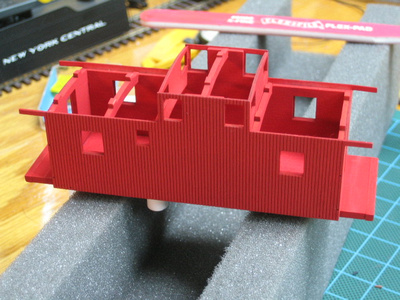

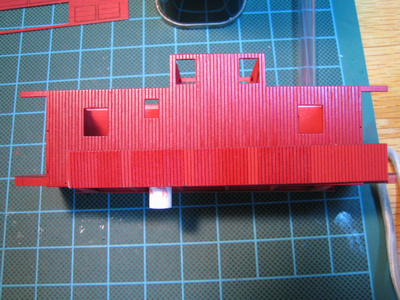

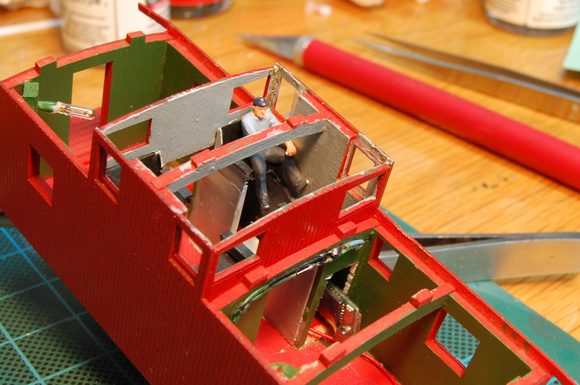

First, the kit is by American Model Builders from their Laserkit series and is of a Norfolk and Western class CF caboose. The prototype was a wood sided, steel underframed caboose that was produced between 1914 and 1924, with some staying in service in some capacity into the 60's.

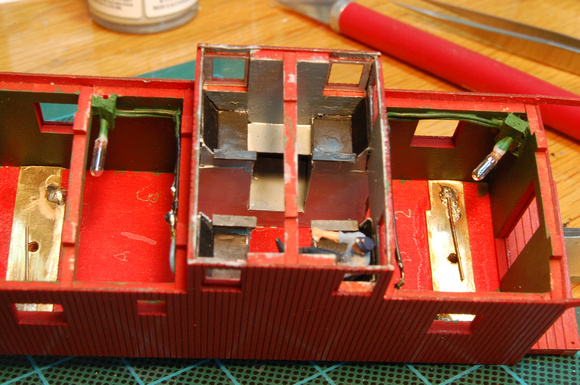

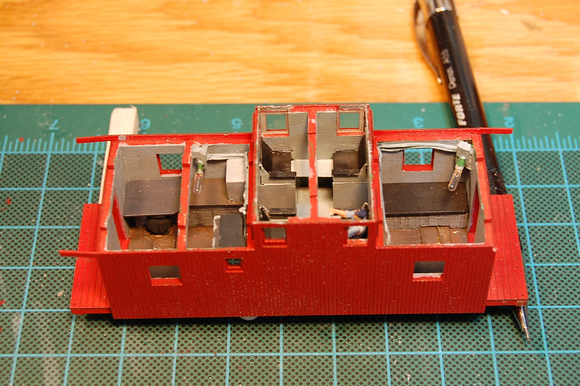

The kit comes relatively complete, but did need some extras:

- Andrews "caboose" trucks from Eastern Car Works

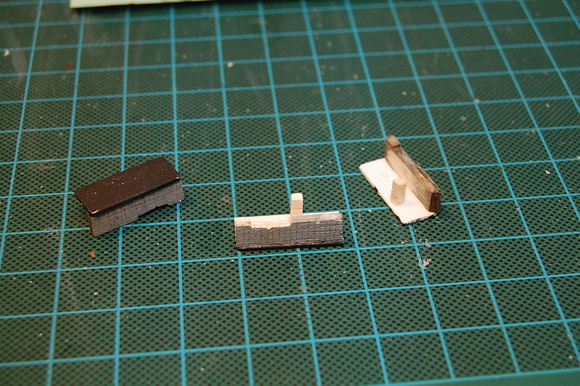

- Brake gear detail kit from Tichy Train Group. I chose the KC style because of the era that I model (prior to 1940). This kit included the air resevoir / cylinder assembly (one piece on the KC's), various actuating levers and brake wheel. A nice set.

- Caboose detail kit from Detail Associates. This contains many pre-bent grabs, ladders and some bolt details. The grabs are generic and I haven't decided how many are going to be useful - more later.

- Paint. The two big ones for me are Caboose red and Soo Line red, both from floquil. The rest of the paints are various grays, blacks and brown acryllics.

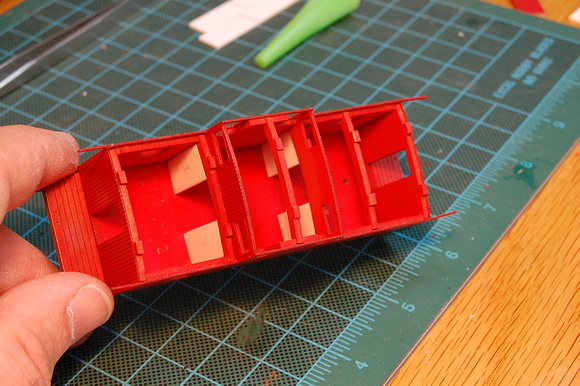

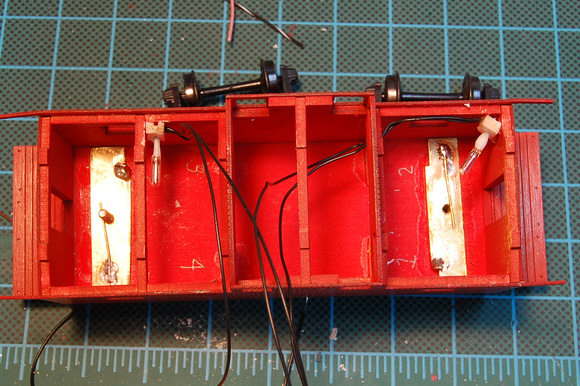

I also decided to add lights (internal), so the additional stuff was aquired:

- Miniatronics 1.3mm 12v bulbs

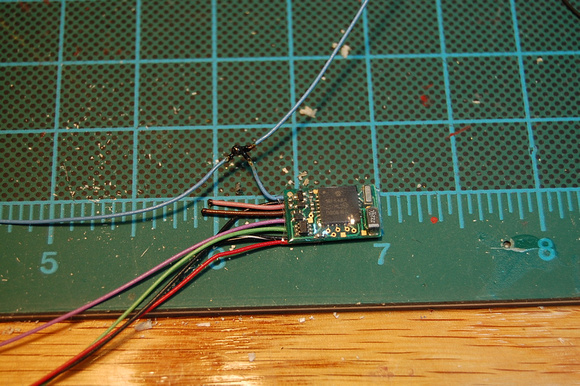

- TCS FL4 decoder (four output, function only)

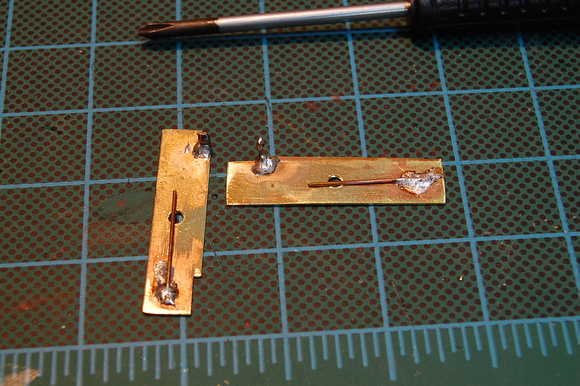

- Axle wipers from Richmond Controls

I've taken a bunch of pictures over time while building this and will present a few at a time until caught up. Bear with me, and wipe off that glassy eyed stare!

More to come...

fluesheet

Since then I've worked on it off and on and decided it'd be worthwhile to post my progress (even if the updates are six months behind).

First, the kit is by American Model Builders from their Laserkit series and is of a Norfolk and Western class CF caboose. The prototype was a wood sided, steel underframed caboose that was produced between 1914 and 1924, with some staying in service in some capacity into the 60's.

The kit comes relatively complete, but did need some extras:

- Andrews "caboose" trucks from Eastern Car Works

- Brake gear detail kit from Tichy Train Group. I chose the KC style because of the era that I model (prior to 1940). This kit included the air resevoir / cylinder assembly (one piece on the KC's), various actuating levers and brake wheel. A nice set.

- Caboose detail kit from Detail Associates. This contains many pre-bent grabs, ladders and some bolt details. The grabs are generic and I haven't decided how many are going to be useful - more later.

- Paint. The two big ones for me are Caboose red and Soo Line red, both from floquil. The rest of the paints are various grays, blacks and brown acryllics.

I also decided to add lights (internal), so the additional stuff was aquired:

- Miniatronics 1.3mm 12v bulbs

- TCS FL4 decoder (four output, function only)

- Axle wipers from Richmond Controls

I've taken a bunch of pictures over time while building this and will present a few at a time until caught up. Bear with me, and wipe off that glassy eyed stare!

More to come...

fluesheet