SeriousSam said:

...So I am going to install grab irons and AC units and MU cables and try to make them as real as possible. I just hope I dont mess my locomotives up

May I suggest that you then first practice on an older, or secondary engine first? Just like you would want to get an old train-set car to practice painting, decaling, and weathering techniques, you can get practice on an older engine, or even a car. Or, just order a body assembly set from Atlas (what, $12, $15 at most for an undecorated GP38 shell, handrails, etc., etc.?).

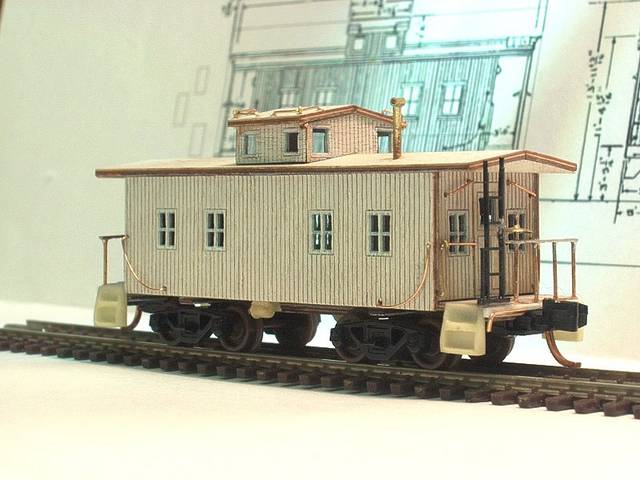

How about super-detailing a caboose for practice? I took a Model Power caboose from a train set and practiced with it. I removed the roofwalks, cut off the mounting lugs and plugged the mounting holes in the caboose, then I carefully sanded the roofwalks until they were realistically thin, and glued them back on. I got a smokestack detail piece, and installed it with some .006" wire for supports. Shaved off all the grab irons and redid separates with .008" wire (even the curved ones). And then scratchbuilt ladders out of .008" wire, brake wheel stands out of .010" styrene, and uncoupling levers out of .008" wire. The only piece I didn't already have was the smokestack, so it was cheap. Now I have some generic caboose that doesn't look toyish, and I got alot of practice out of it.

Now, I wouldn't use all sorts of expensive detailing parts for a practice engine. For example, it's pretty straightforward to glue on an A/C unit, so you don't need to do that on your practice engine. But get some grab irons from BLMA, a GMM diesel detail set, the tools you think you'll need, and get comfortable with the process. As you do this, you'll see what methods and tools work for you. No stress, no worries. If you gouge out a grab iron too much, or mess up the angle of a grab iron, it's no biggie. We all make mistakes like that when we are detailing engines. The trick is that we also learn how to fix those mistakes.

Down the line, after you've done several engines and want to try something more advanced, come back to your practice engine and add finer handrails with a GMM handrail set and some .008" wire. Bend your own sanding lines out of brass wire. scratchbuild air reservoir tanks. It's not expensive, it just takes some time and practice.

---jps