Hello

I was making a ladder in my Ambrose ship.

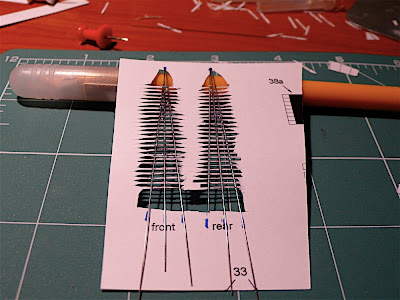

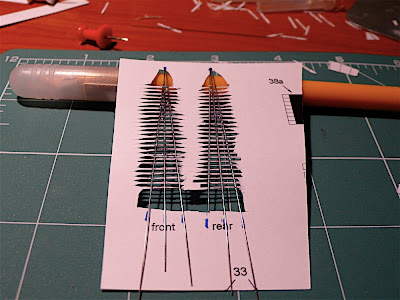

Here you can see

the ladder made from paper.

Or you can make a hybrid where the vertical parts (sorry for the name

but I don't know how to call it in english) are made from steel wire

and the rungs from paper (or opposite as you wish). I have a picture

here that I did not used in my Ambrose thread.

I think that the idea is clearly shown on the picture. You cut out the

rungs from paper using a knife. It is really doable try and you will see.

Then you glue the wires in right places. I think that it is also possible

to make it whole from wires (but I didn't try). You make a square

hole in a piece of paper and glue the rungs to the paper on both sides

of the hole. Then you glue the vertical wires to the rungs.