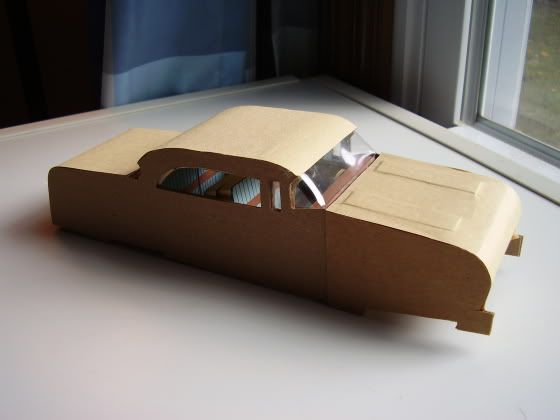

Those Caribbeans are indeed beautiful. I hope this model can come close to doing the real car justice.

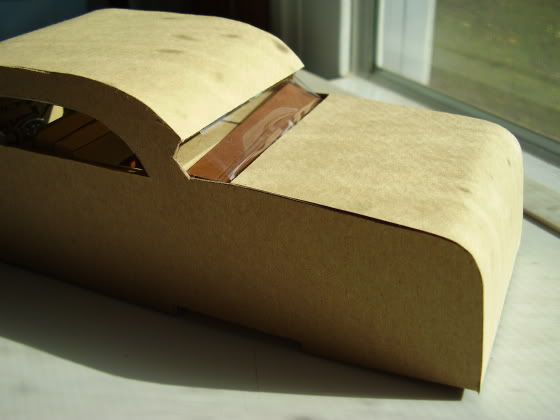

Instead of using the corrugated slabs (above posts)for seat cushions, I made the cushions and seat backs as strip-and-panel boxes. If I had used the corrugated pieces, I would have had to paper the fluted edges, and I still would have had to clad them with cardboard strips and panels.

The front seat is done, and is dry test-fitted into the interior.

It seems to take as long to do an interior as it does to do an entire exterior.

Instead of using the corrugated slabs (above posts)for seat cushions, I made the cushions and seat backs as strip-and-panel boxes. If I had used the corrugated pieces, I would have had to paper the fluted edges, and I still would have had to clad them with cardboard strips and panels.

The front seat is done, and is dry test-fitted into the interior.

It seems to take as long to do an interior as it does to do an entire exterior.